Solution: Internal Rotating Inspection System (IRIS)

Solution: Internal Rotating Inspection System (IRIS)

Internal Rotating Inspection System (IRIS)

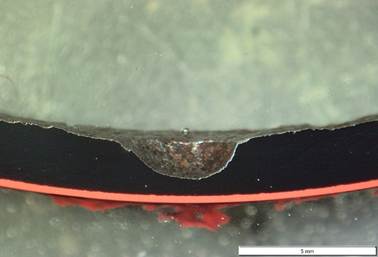

IRIS tube testing is a well-known wall thickness measurement technique for heat exchanger tubes. IRIS is basically an Ultrasonic Testing (UT) technique for thickness measurements under immersion. Ultrasonic beams are reflected against a rotating mirror to measure remaining tube thickness. To do so, tubes must be filled with water for UT transmission. Continuous water supply is needed to flood the tubes and to rotate the mirror mounted on the IRIS probe. This way it is possible to measure wall thickness of a tube for over all its length and circumference.

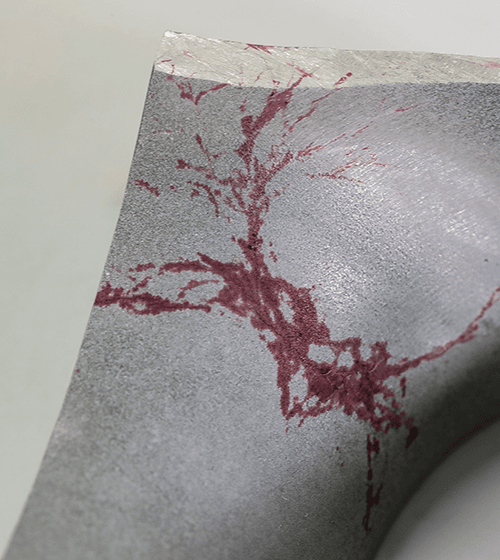

TÜV AUSTRIA is using the state-of-the-art IRIS inspection solution from EddyFi. Each tube data is saved and can be displayed as C-Scan (a 2D deployed view of the tubes) for precise wall loss localization. IRIS can be used on ferro-and non-ferromagnetic materials and is often used as a secondary tube testing technique or back-up to the much faster electromagnetic inspection techniques such as ECTT, RFT, NFT and MFL.