Solution: Corrosion analysis sprinkler systems

Solution: Corrosion analysis sprinkler systems

Corrosion analysis sprinkler systems

In which region do you need this solution?

Corrosion analysis sprinkler systems

By a combination of different knowledge domains, TÜV AUSTRIA has the ideal expertise to find the root causes, map the problem and suggest remediation actions in case your sprinklers are subjected to corrosion problems.

Sprinkler systems, which are usually made from carbon steel or galvanized steel, are susceptible to corrosion, which can arise from several factors. In wet systems, periodic testing may introduce fresh, oxygenated water, accelerating corrosion. In dry systems, improper drainage can leave residual water behind, contributing to corrosion. Additionally, air pockets trapped at high points in the piping can further promote localized corrosion. The issue may be exacerbated by microbiologically influenced corrosion (MIC), which intensifies the degradation process. While using higher-alloyed materials could mitigate corrosion, this solution is often economically unfeasible.

Start from a failure analysis to identify the root cause, perform water analysis and NDT to assess the extent of the problem and provide analysis and remedial actions.

Sprinkler systems, which are usually made from carbon steel or galvanized steel, are susceptible to corrosion, which can arise from several factors. In wet systems, periodic testing may introduce fresh, oxygenated water, accelerating corrosion. In dry systems, improper drainage can leave residual water behind, contributing to corrosion. Additionally, air pockets trapped at high points in the piping can further promote localized corrosion.

The issue may be exacerbated by microbiologically influenced corrosion (MIC), which intensifies the degradation process. While using higher-alloyed materials could mitigate corrosion, this solution is often economically unfeasible.

TÜV AUSTRIA provides a structured, multidisciplinary approach to diagnose and resolve corrosion issues in sprinkler systems. By combining failure analysis, water analysis, and non-destructive testing (NDT), we identify the root causes, assess the extent of damage, and deliver practical, data-driven remediation advice.

Main benefits of TÜV AUSTRIA’s corrosion analysis:

- A unique combination of expertise in corrosion, non-destructive testing (NDT), and water analysis.

- An integrated approach guiding clients from thorough damage assessment to practical advice and corrective measures.

Failure analysis

By means of a failure analysis, the exact root cause of the degradation is determined. A representative section of the sprinkler piping is removed for destructive analysis in the laboratory. A failure analysis typically includes following investigations: visual examination of the internal and external surface, light microscopic and/or scanning electron microscopic study on cross-sections through the pipe and analysis of the deposits/corrosion products.

Evaluation of the sprinkler water

To determine the corrosion risk associated with a certain water quality a water analysis is typically performed. Samples of the water are taken at different locations in the system (reservoir, at the start and at the end of the system, dead ends). Based on the results of the water analysis a general estimation of the corrosion risk towards the material of the sprinkler piping is made.

A typical analysis includes:

1. determination of chemical parameters relevant to corrosion (pH, ionic composition, …) and determination of the corrosivity of the water.

2. determination of the risk for microbiologically influenced corrosion by semi-quantitative or quantitative determination of different groups of bacteria

Non-destructive testing

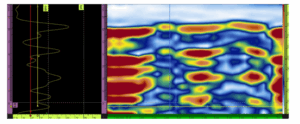

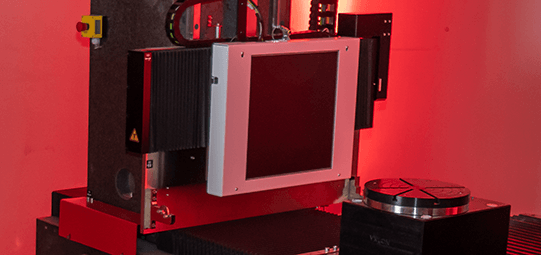

Through its NDT department, TÜV AUSTRIA Belgium can assess the condition of the sprinkler installation. Techniques being used consist of PAUT corrosion mapping to determine the wall thickness the piping, as well as remote visual inspection using endoscopic inspection to identify deposits and tubercles inside the tubes.

The water reservoir (sprinkler tank) can be inspected using a submarine for underwater visual inspection. All information gathered from the various investigations will be consolidated and used as the foundation for providing advice and recommending corrective actions.