The coating on your installation is essential since it serves several purposes, like protection and aesthetics. But how can you ensure good performance of the coating for your application?

It all starts with…

Finding the right coating…

Matching the right coating to the right application requires experience. One of the most important factors to consider in selecting the right coating is climate. You do not want your coating to start peeling off after exposure to e.g. atmospheric conditions with corrosion of your installation as a result.

This is why standards exist that recommend coating systems to be used for different conditions. With regard to atmospheric conditions ISO 12944 stipulates comprehensive guidelines for coating systems to protect steel substrates. The recommended coating systems depend on the corrosivity class of the environment where the coating is to be used (e.g. rural environment, industrial climate, maritime climate, …).

Furthermore, this ISO standard also specifies which coating tests and coating test durations are required to verify that a coating system can be applied in a particular climate and what the expected life span is. Likewise, to verify the resistance of coatings to certain aggressive media in advance, exposure tests can be performed in laboratories to test the suitability of the coatings.

…applying it to perfection

It is important to keep in mind that your coating will only be as effective as its application.

Application on site is a delicate matter that concerns many parameters to be kept in check, like for instance:

- Roughness and cleanliness of the substrate;

- Dew point;

- Drying times;

- Thickness.

Poor application can result in premature failure of the coating, irrespective of the fact that a good coating was selected. It is therefore advisable that you are supported by a qualified coating inspector (such as a NACE certified or FROSIO certified inspector) during that process and after application.

Beside visual inspections, diverse coating measurements can be performed, like:

- Thickness measurements;

- Adhesion tests;

- Roughness measurements;

- Hardness measurements.

… and periodically run coating tests

Once the coating is applied it is advised to have your coating inspected periodically to follow up the condition and detect coating degradation in an early stage.

A coating test typically includes visual examination but can also include other non-destructive techniques, such as on-site EIS measurements.

EIS coating tests

Electrochemical impedance spectroscopy (EIS) is a non-destructive technique to measure the general barrier properties of coatings. More specifically water and ion permeability of coatings can be determined as a function of time.

This information is particularly valuable for:

- quality control of a freshly applied coating;

- comparison of performance of different coatings;

- follow-up of coatings in situ.

The barrier properties of the coating are assessed from the impedance spectrum, typically combining the resistive and capacitive behaviour of the coating.

EIS testing has the following beneficial properties:

- differences in coating performance can already be confirmed before there are any visual signs of degradation;

- corrosion processes taking place underneath the coating can be measured as well;

- EIS measurements can be done on aboveground as well as underground coated structures.

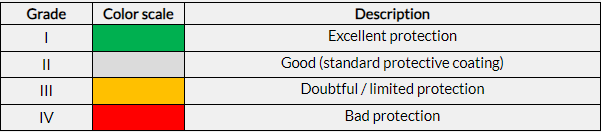

At TÜV AUSTRIA Belgium, formerly METALogic, general evaluation of the coating is performed based on the classification system presented below. This grading system is based on extended literature, laboratory and field study of coatings. It takes into consideration the stage of a coating’s degradation, its barrier and capacitive properties, all received from analysis of the Bode and Nyquist plots.

Ready for professional coating tests? Simple, get in touch!

As mentioned above, coating tests will provide you with insights in the quality of your coating and give you the possibility to act before damage occurs.

We have:

- experienced engineers and certified coating inspectors in house to perform on-site visual inspections;

- more than 10 years of experience in EIS measurements;

- a well-equipped lab to perform coatings tests and to examine coating failures.